Electronic contact cleaner sprays are versatile and essential tools for maintaining and optimizing the performance of electronic devices and components. These sprays are designed to remove dust, dirt, contaminants, and oxidation from electrical connections, connectors, and other sensitive electronic parts. In this comprehensive guide, we will explore the numerous benefits of using electronic contact cleaner sprays, their applications, and best practices for their safe and effective use.

Electronic devices are an integral part of modern life, from smartphones and computers to household appliances and automotive systems. These devices rely on various electronic components, connectors, and circuitry to function correctly. Over time, dust, dirt, and oxidation can accumulate on these components, leading to decreased performance, connectivity issues, and even device failures.

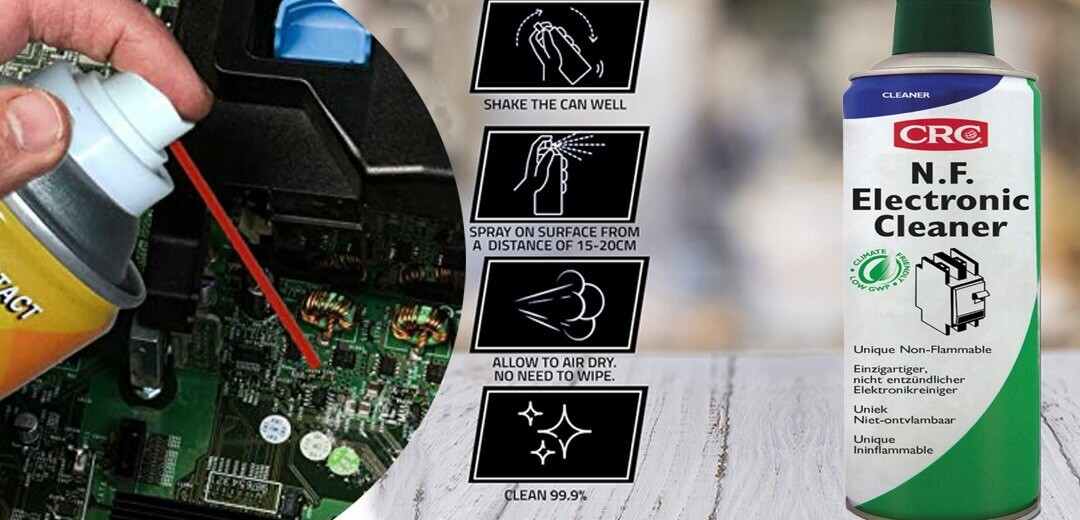

Electronic contact cleaner sprays, often referred to simply as contact cleaners, are specialized cleaning solutions designed to address these issues. They are widely used by electronics enthusiasts, technicians, and professionals to clean and maintain electronic equipment. Let's delve into the key benefits of using electronic contact cleaner sprays.

Benefits of Using Electronic Contact Cleaner Sprays

1. Dust and Debris Removal

One of the primary functions of electronic contact cleaner sprays is to remove dust and debris from electronic components. Dust particles can settle on circuit boards, switches, connectors, and other sensitive parts of electronic devices. Over time, this accumulation can impede the flow of electricity, affect signal quality, and lead to overheating. Electronic contact cleaner sprays effectively dislodge and remove these contaminants, restoring optimal functionality.

2. Corrosion Prevention

Corrosion can be a significant concern, especially in humid or corrosive environments. Some electronic contact cleaner sprays contain corrosion inhibitors, which create a protective barrier on metal contacts and connectors. This barrier helps prevent oxidation and corrosion, ensuring the longevity and reliability of electronic connections.

3. Restoring Electrical Conductivity

Oxidation and contaminants on electronic contacts can hinder electrical conductivity, leading to issues such as signal loss, poor audio or video quality, and intermittent connections. Electronic contact cleaner sprays can dissolve and remove these barriers, effectively restoring proper electrical conductivity.

4. Safe for Electronics

High-quality electronic contact cleaner sprays are formulated to be safe for use on a wide range of electronic components. They are non-conductive and evaporate quickly, leaving no residue behind. This means that when used correctly, these sprays won't damage sensitive electronics or leave behind harmful substances that could cause further issues.

5. Extended Device Lifespan

Regular maintenance with electronic contact cleaner can extend the lifespan of electronic devices. By keeping internal components clean and free from damage caused by contaminants or corrosion, you can ensure that your devices continue to operate reliably for years to come.

6. Versatility

Electronic contact cleaner sprays are incredibly versatile and find applications in various industries and settings. Some common uses include:

Computers and Laptops: Cleaning internal components, circuit boards, and connectors.

Audio/Video Equipment: Enhancing the quality of audio and video signals by cleaning connectors, jacks, and switches.

Automotive Electronics: Maintaining electrical connections in vehicles, including spark plug wires, sensors, and ignition systems.

Home Electronics: Cleaning remote controls, game consoles, and home theater systems.

Industrial Equipment: Ensuring the reliability of machinery and control systems in manufacturing environments.

Now, let's take a closer look at each of these benefits and explore why electronic contact cleaner sprays are indispensable in electronics maintenance and repair.

1. Dust and Debris Removal

Dust and debris are ubiquitous, and they have a knack for finding their way into electronic devices and equipment. When dust accumulates on electronic components, it can insulate them and trap heat, leading to overheating and reduced performance. Furthermore, dust can contain conductive particles, increasing the risk of short circuits.

Electronic contact cleaner sprays use a combination of a solvent and a propellant to dislodge and remove dust and debris. The solvent's ability to dissolve contaminants, coupled with the propellant's force, ffectively clears away particles that can compromise the proper functioning of electronics.

Applications:

- Cleaning computer keyboards and internal components.

- Removing dust and debris from gaming consoles and controllers.

- Maintaining the cleanliness of electronic instruments and test equipment.

- Preventing dust buildup on circuit boards and power supplies.

2. Corrosion Prevention

Corrosion, or the gradual degradation of metal due to chemical reactions with the environment, can be a severe threat to electronic connections and components. It's especially problematic in environments with high humidity or exposure to corrosive substances.

Certain contact cleaner sprays are formulated with corrosion inhibitors. These inhibitors form a protective layer on metal surfaces, preventing moisture and oxygen from reaching the metal. As a result, the chances of oxidation and corrosion are significantly reduced. This protective barrier can add years to the life of electronic components and connectors.

Applications:

- Protecting battery terminals from corrosion in automotive and marine applications.

- Preventing corrosion on electrical contacts in outdoor equipment.

- Extending the lifespan of connectors in industrial control systems.

3. Restoring Electrical Conductivity

Over time, oxidation and contaminants can accumulate on metal contacts and connectors, hindering electrical conductivity. This can lead to various issues, such as poor audio or video quality, unreliable data transmission, and device malfunctions.

Electronic contact cleaner sprays are designed to dissolve and remove these barriers. By effectively cleaning the contacts, these sprays restore proper electrical conductivity, ensuring the smooth flow of electrical signals and data.

Applications:

- Enhancing the performance of audio and video connectors and cables.

- Improving the reliability of connectors in networking equipment.

- Restoring functionality to switches and controls in electronic devices.

4. Safe for Electronics

One of the critical considerations when using any cleaning product on electronic components is safety. Electronic contact cleaner sprays are engineered to be safe for use on a wide range of electronic devices. They are non-conductive, which means they won't conduct electricity and potentially cause short circuits. Additionally, they evaporate quickly, leaving no residue behind that could interfere with the normal operation of electronics.

This safety aspect is crucial when cleaning delicate and sensitive components like circuit boards, microchips, and connectors. Users can have confidence that they are not inadvertently causing harm to their electronics.

Applications:

- Cleaning and maintaining circuit boards in computers and electronic gadgets.

- Ensuring safety when cleaning high-voltage equipment in industrial settings.

- Protecting sensitive electronic components during maintenance and repair.

5. Extended Device Lifespan

Electronics are a significant investment, and users naturally want their devices to last as long as possible. Regular maintenance with electronic contact cleaner sprays can contribute to the prolonged lifespan of these devices. By preventing the accumulation of contaminants and the onset of corrosion, users can avoid costly repairs or replacements.

Moreover, electronic devices that function optimally tend to have a longer life expectancy. Clean and well-maintained components are less likely to overheat, suffer from connectivity issues, or experience sudden failures.

Applications:

- Extending the life of laptops and desktop computers.

- Ensuring the reliability of critical electronic systems in industrial environments.

Prolonging the lifespan of home entertainment systems and gaming consoles.

.jpeg)

.jpg)