Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for countless electronic devices we rely on daily. From smartphones and laptops to medical equipment and automotive systems, PCBs are ubiquitous. However, to ensure the reliability and longevity of these electronics, protective measures are often necessary. This is where PCB conformal coating spray comes into play. In this comprehensive exploration, we will delve into how PCB conformal coating spray is revolutionizing the electronics industry, enhancing the performance and lifespan of electronic devices, and simplifying the manufacturing and maintenance processes.

The Basics of PCB Conformal Coating

1. What is PCB Conformal Coating?

PCB conformal coating is a protective material applied to the surface of printed circuit boards. This coating serves several crucial purposes, primarily:

Protection: It shields PCBs from various environmental factors, including moisture, dust, chemicals, and temperature fluctuations, which can otherwise compromise their functionality.

Insulation: Conformal coatings insulate and safeguard the circuitry from electrical interference and short circuits.

Enhanced Durability: Coated PCBs are more robust and less prone to physical damage, which is especially vital in applications subject to vibrations or mechanical stress.

2. Types of Conformal Coatings

There are various types of conformal coatings available, each with its own unique properties and applications:

Acrylic: Acrylic conformal coatings offer excellent moisture and UV resistance, making them suitable for outdoor applications.

Silicone: Silicone coatings provide high thermal resistance, flexibility, and protection against extreme temperatures.

Urethane: Urethane conformal coatings are known for their durability and resistance to chemicals and abrasion.

Parylene: Parylene coatings are ultra-thin and provide uniform coverage, ideal for intricate and delicate electronic components.

Epoxy: Epoxy coatings offer superior adhesion and protection against humidity and moisture.

The Impact of PCB Conformal Coating Spray

3. Enhancing Reliability and Longevity

The application of PCB conformal coating spray significantly enhances the reliability and longevity of electronic devices. By creating a protective barrier over the PCB, it guards against external elements that could otherwise lead to corrosion, electrical shorts, or component failure. This, in turn, reduces the likelihood of costly repairs or replacements, improving the overall lifespan of the electronics.

4. Waterproofing Electronics

One of the most transformative effects of PCB conformal coating spray is its ability to waterproof electronic devices. This is particularly valuable in devices that may be exposed to moisture or liquids, such as medical equipment, outdoor electronics, and marine applications. By sealing the PCB, conformal coating spray ensures that vital electronics remain operational even in wet environments.

5. Mitigating Environmental Hazards

Electronics often operate in challenging environments, from factories with chemicals to outdoor weather conditions. Conformal coating spray acts as a protective shield against these environmental hazards. For instance, in industrial settings, it shields PCBs from corrosive chemicals, reducing the risk of damage and maintaining the integrity of critical systems.

6. Facilitating Miniaturization

As electronics continue to shrink in size, PCB conformal coating spray becomes indispensable. Miniaturized components are more vulnerable to environmental damage due to their reduced size and increased component density. Conformal coatings offer a way to protect these delicate components while enabling the design of smaller, more compact devices.

PCB Conformal Coating in Various Industries

7. Electronics Manufacturing

In the electronics manufacturing industry, PCB conformal coating spray has transformed the way products are assembled and tested. By applying conformal coatings, manufacturers can ensure the reliability of their products, reduce the risk of defects, and streamline quality control processes.

8. Aerospace and Defense

Aerospace and defense applications demand the highest levels of reliability and durability. PCB conformal coatings are extensively used to protect electronics in aircraft, missiles, radar systems, and military vehicles. These coatings safeguard critical systems from extreme temperatures, humidity, and mechanical stress, ensuring mission-critical functionality.

9. Medical Devices

In the medical field, PCB conformal coatings are instrumental in enhancing the reliability and safety of medical devices. From pacemakers to diagnostic equipment, medical devices must perform flawlessly. Conformal coatings protect the sensitive electronics within these devices from bodily fluids, sterilization processes, and external contaminants.

10. Automotive Electronics

The automotive industry relies heavily on electronic systems for vehicle control, safety features, and infotainment. Conformal coatings play a pivotal role in ensuring the longevity and reliability of these systems. They protect against temperature extremes, vibrations, and exposure to road conditions, contributing to overall vehicle safety and performance.

11. Consumer Electronics

In the world of consumer electronics, where devices are constantly exposed to different environments, conformal coatings are increasingly utilized. Smartphones, tablets, and wearables benefit from conformal coatings that protect against dust, moisture, and accidental spills, enhancing the durability of these often expensive devices.

Application Methods and Considerations

12. Application Methods

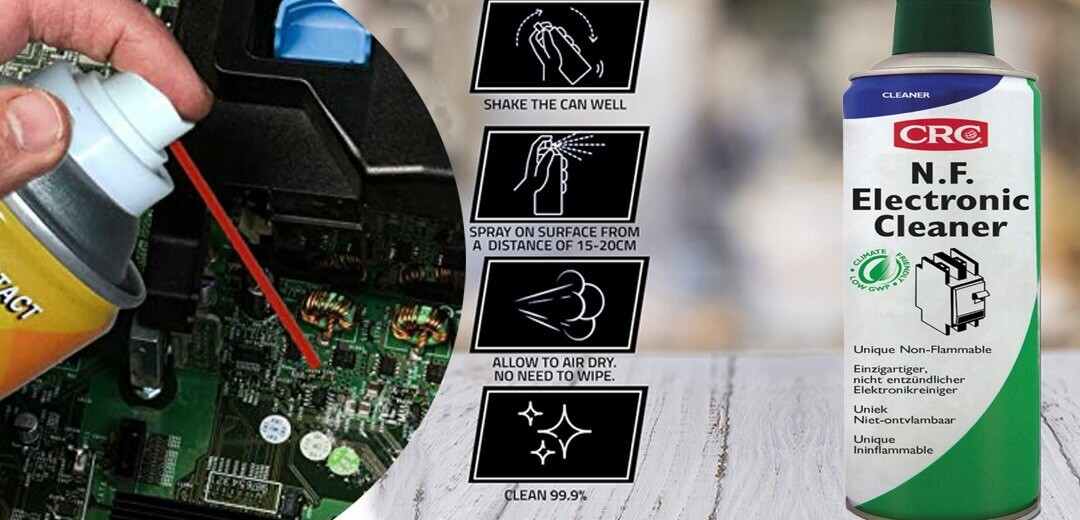

Applying PCB conformal coating spray requires careful consideration of the method chosen:

Dip Coating: Involves immersing the PCB into a vat of conformal coating material, ensuring even coverage.

Spray Coating: Utilizes a fine mist of coating material sprayed onto the PCB's surface, offering precision and control.

Brush Coating: Involves manually brushing the conformal coating onto the PCB, ideal for small-scale or touch-up applications.

Selective Coating: This method targets specific areas on the PCB, offering customization and control over where the coating is applied.

13. Material Compatibility

Selecting the right conformal coating material is critical. It must be compatible with the components on the PCB and the intended operating environment. Compatibility testing ensures that the coating does not interfere with electrical connections or affect the performance of sensitive components.

14. Thickness and Uniformity

Achieving the correct coating thickness and uniformity is essential for optimal protection. Too much coating can cause overheating or interfere with connectors, while too little may not provide adequate protection. Quality control measures are vital to ensure consistent and reliable results.

The Future of PCB Conformal Coating Spray

15. Advancements in Nanotechnology

The future of PCB conformal coating spray is likely to witness significant advancements in nanotechnology. Nanocoatings, with their ultra-thin layers, will become more prevalent, providing superior protection without adding bulk or weight to electronic devices. These coatings will also offer advanced functionalities, such as self-healing capabilities to repair minor damage.

16. Integration of Smart Coatings

Smart coatings, equipped with sensors and monitoring capabilities, may revolutionize the way we view PCB conformal coatings. These coatings could provide real-time data on the condition of the PCB and surrounding environment, offering early warning signs of potential issues and enabling proactive maintenance.

17. Sustainability and Eco-Friendly Coatings

The electronics industry is increasingly focused on sustainability and eco-friendliness. Future developments in conformal coatings will likely include more environmentally friendly options that reduce the use of harmful chemicals and are easier to dispose of responsibly.

In a world where electronics are deeply ingrained in our daily lives, PCB conformal coating spray is a silent hero, working diligently to protect and enhance the reliability of these devices. As we've explored, the impact of PCB conformal coating spray spans across various industries, from aerospace to medical devices, ensuring the seamless operation of critical systems. In the midst of these technological advancements, it's crucial to highlight the role of innovative companies like "Paltools Stores."

"Paltools Stores" has been at the forefront of providing high-quality PCB conformal coating sprays, enabling businesses across industries to safeguard their electronics, enhance durability, and mitigate environmental hazards. Their commitment to offering cutting-edge solutions and staying on top of industry trends positions them as a key player in the electronics protection landscape.

As we peer into the future, we anticipate remarkable developments in nanotechnology, the integration of smart coatings, and a greater emphasis on sustainability in the conformal coating arena. With "Paltools Stores" and similar forward-thinking companies leading the way, the electronics industry is poised to embrace these transformative changes, ensuring that PCB conformal coating spray continues to change lives by making our electronic devices more reliable, durable, and environmentally conscious.

.jpeg)

.jpg)